濟(jì)南鋁板不上色有哪些原因?

1、濟(jì)南鋁板http://www.pdadn.com/陽極氧化膜厚缺乏,處理的辦法是檢查陽極氧化技術(shù)是不是標(biāo)準(zhǔn),看溫度,電壓,導(dǎo)電等要素是不是安穩(wěn),若有反常,請(qǐng)相應(yīng)調(diào)整標(biāo)準(zhǔn)之,若無反常,可恰當(dāng)延長氧化時(shí)刻,確保膜厚合格。濟(jì)南鋁板染液pH值太高,可用冰醋酸將pH值調(diào)至標(biāo)準(zhǔn)值。

Jinan anodic aluminum oxide film thickness deficiency way to deal is to check the anodizing technology is not the standard, see the temperature, voltage, electrical conductivity and other factors is not secure, if unusual, please adjust the appropriate standards, if not unusual, may be appropriate to extend the oxidation time to ensure qualified film thickness. Jinan aluminum dyebath pH is too high, can be used acetic acid and the pH was adjusted to the standard value.

2、濟(jì)南鋁板氧化后工件在水槽中放置時(shí)刻太久,發(fā)起及時(shí)染色,假如這種狀況現(xiàn)已發(fā)作,可將工件放在陽極氧化槽中或硝酸中和槽中恰當(dāng)活化處理后再進(jìn)行染色,作用會(huì)很好,選用染料不妥,需選用合適染料。

After placing the workpiece Jinan aluminum oxide in the sink long time, initiate timely staining, if this situation has been attack, the workpiece can be placed in the anodizing bath or nitric acid neutralization tank proper activation treatment after dyeing, the role will be well, the choice of dye wrong, need to choose the right dye.

3、濟(jì)南鋁板染料已分化或霉變,此刻需替換染料,濟(jì)南鋁板氧化溫度過低,致使皮膜致密:可恰當(dāng)進(jìn)步氧化溫度。

Jinan aluminum dye differentiated or mildew, and now need to replace the dye, Jinan aluminum oxidation temperature is too low, resulting in a dense film: the progress of the oxidation temperature may be appropriate.

4、濟(jì)南鋁板http://www.pdadn.com/導(dǎo)電不良,可能陽極銅桿或陰極鉛板觸摸不良所示批量導(dǎo)電不良,留意清潔陽極銅桿及陰極鉛板,確保觸摸良好。

Jinan poor conductivity of aluminum, copper rod anode or cathode may touch the bad stereotype bulk conductivity shown poor attention to cleaning the anode and cathode copper rod stereotype, to ensure a good touch.

公司新聞排行

- 鋁單板變形后的處理方法

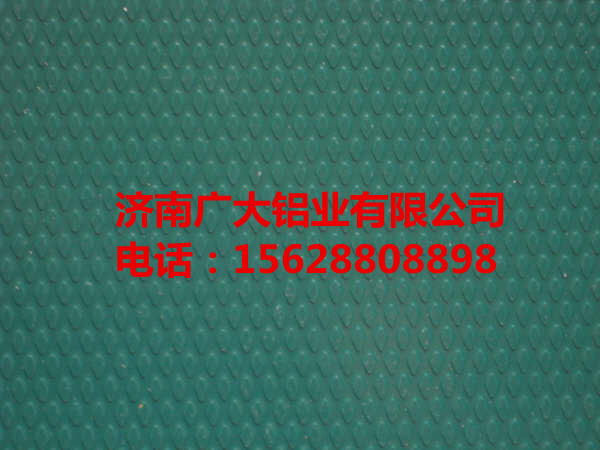

- 花紋鋁板的優(yōu)點(diǎn)有哪些

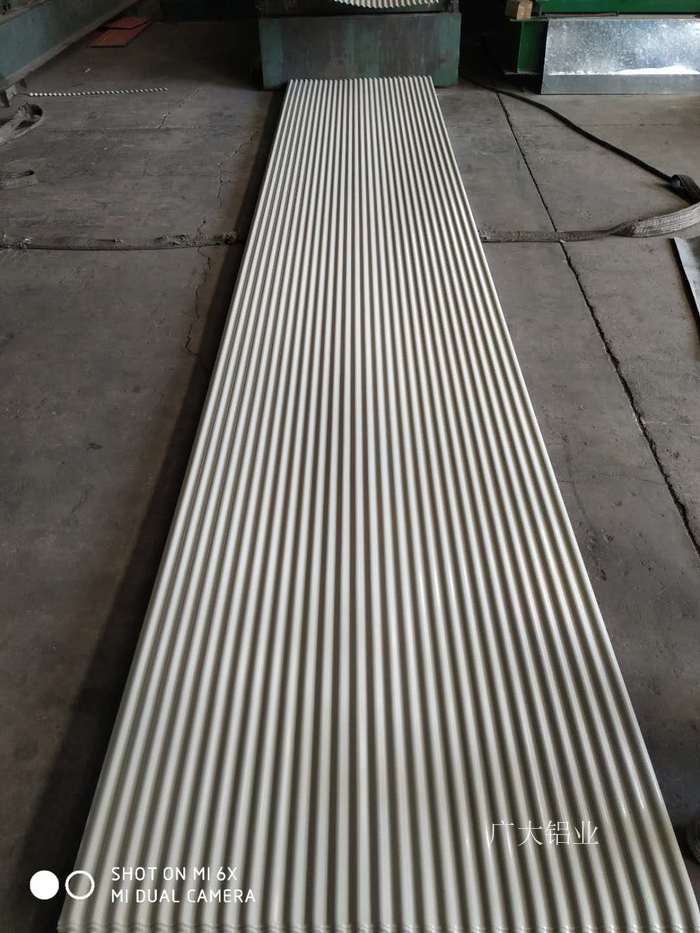

- 合金鋁板表面拉絲處理工藝

- 橘皮花紋鋁板的分類與應(yīng)用

- 花紋鋁板在建筑行業(yè)的應(yīng)用

- 鋁板廠家告訴你為什么鋁板表面要進(jìn)行貼膜?

- 濟(jì)南幕墻鋁單板規(guī)格有什么不同

- 濟(jì)南鋁單板幕墻多樣性的類型

- 濟(jì)南外墻鋁單板的創(chuàng)新設(shè)計(jì)與環(huán)保理念

- 鋁板廠家談?wù)勪X板在運(yùn)輸過程中是如何存放的?

行業(yè)知識(shí)排行

- 鋁板幕墻產(chǎn)品介紹

- 什么是壓花花紋鋁板

- 合金鋁板安裝需要多長時(shí)間

- 常用鋁板材質(zhì)型號(hào)有哪些?

- 氧化鋁板和普通鋁板如何區(qū)分

- 彩色合金鋁板使用的注意事項(xiàng)

- 濟(jì)南氟碳鋁單板出現(xiàn)漏水問題應(yīng)該怎么解決?

- 什么是濟(jì)南鋁蜂窩板,到底好不好?

- 為什么鋁板加工時(shí)需要注意精準(zhǔn)度?

- 如何選購好的鋁板